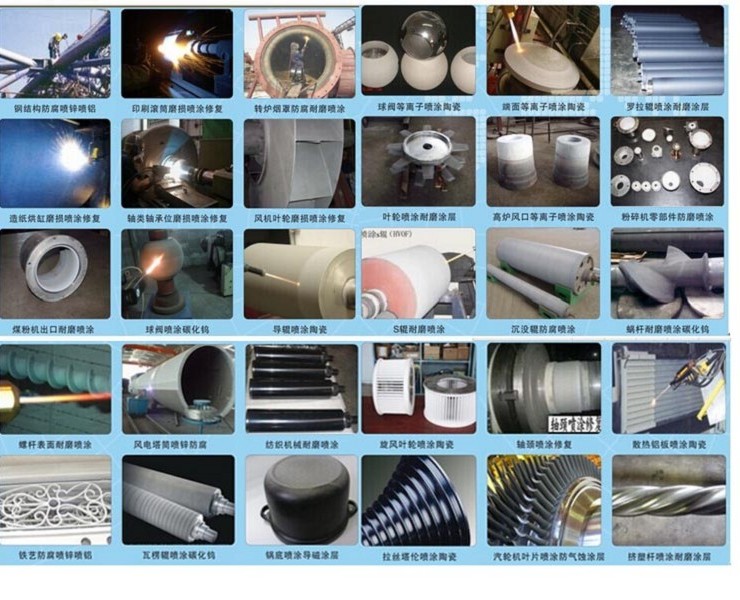

Product Categories

Thermal spray equipment - Plasma spray equipment

- HVOF spray equipment

- Arc spray equipment

- Plastic spray equipment

Auxiliary equipment - coating thickness gauge

- Screw air compressor

- Sandblasting machine

- Dust collect system

- Two axis spray manipulator

- Sound proof spraying room

Coating services Coating material

Recommended Products

Contact Us

Guangzhou Sanxin Metal S&T Co., Ltd.

Address£ºFLAT/RM 1405B 14/F THE BELGIAN BANK BUILDING NOS. 721-725 NATHAN ROAD MONGKOK

Contact person:Mr Green Wu£¨Manager£©

Tel:0086 13533137978

Fax:0086 20 28651601

Email:green_wu@hotmail.com

Skype:green_wu@hotmail.com

facebook:green_wu@hotmail.com

Whatsapp:+8613533137978

Wechat:oneday_kjt

QQ:3839269

Plastic spray equipment

- Product name£ºThermal spray equipment

- Description£ºTo spray all kinds of plastic powder for anti corrosion,such epoxy,polythene and so on.

Introduction:

Our company has improved the design on the basis of French SNMI company and Britsh SCHORI company¡¯s Flame spray coating equipment,the improved equipment has a large volume powder feeder which is made of stainless steel.The feeder can supply enough powder to 2 spray gun at the same time.

Because of the powder supply structure of spiral wind type bed with adjustable powder absorber,the powder feeder and spray gun¡¯s long pipe don¡¯t deposit powder.Because the powder feeder doesn¡¯t bear any pressure,it can be loaded the powder without stopping spraying,that keeps the spray gun work long time,stable,well-distributed.The spray gun¡¯s design is special gas mixed and double gas protected structure,which avoid flame¡¯s return.

IN China,Model SX-6000 high power flame spray coating equipment is the sole flame spray equipment used for anti-corrosive construction in big area,the construction efficience is highest.The equipment is suitable for the anti-corrosive construction for chemical device,large container,reserve cabinet,petroleum and natural gas pipe,etc.The anti-corrosive test has standard SY/T,XXXX-2007 which have been listed in,which says that the steel pipe buried underground must be thermal sprayed polythene powder coating outside.

1,Composition: the equipment consists of SX6000 hign power flame spray gun,powder feeder,pipeline and gas adjustable valve.

2,principle: The flame spray is as following. The powder is supplied by the special powder feeder¡¯s soft pipe , with the flame spray gun together,which are assisted by oxygen and ethyne to produce heat.The compressed air is as protected air¡¯s jet flame.Then it warms the plastic powder to be Plastic state or melting state,later the coating is sprayed on the pretreated workpiece¡¯s surface for continuous,well-distributed,non gap plastic coating.

3£¬Feature:

(1),Plastic powder flame spay coating is called flame spray for short.It¡¯s mainly used in big area spray coating construction for anti-corrosive purpose.The following is the feature:it¡¯s thick coating ,spray coating is simple,the device is light and easy to carry,and the device can be made construction on site.

(2),compared to the electrostatic powder coating and sulphur bed coating,the flame spray ¡®s characteristic is as followings :

The device spends low cost,there is no need to build special spray coating booth and drying room.

the device is light and easy to carry,which can make on site construction.The spray coating is not limited with workpiece¡¯s size and shape.

can work in 100% Rh , low temperature,etc.

the powder coating doesn¡¯t contain solvent,there is no need to dry after spray coating,it can be used at once after spray coating.

It can spray all kinds of substrate material,such as steel,concrete and so on .

the spray coating can repair workpieces.It can repair the small defect workpiece whose surface is warmed.the big defect workpiece can be sprayed coating newly.

it¡¯s easy to change powder and color.

Application range:It can directly spray all kinds of coating,such as acidproof,alkali and salt.it doesn¡¯t need to warm the solidifying device ,it¡¯s suitable for on-site big area flame spray construction.It can replace partialy heavy anti-corrosive coating and Fiber Reinforced Plastics lining in anti-corrosion performance,operation technique,operation environment,etc.

Previous£ºOil fuel HVOF spray equipment SX-8000

Next£ºArc spray equipment SX-600