Thermal spray equipment - Plasma spray equipment

- HVOF spray equipment

- Arc spray equipment

- Plastic spray equipment

Auxiliary equipment - coating thickness gauge

- Screw air compressor

- Sandblasting machine

- Dust collect system

- Two axis spray manipulator

- Sound proof spraying room

Coating services Coating material

Guangzhou Sanxin Metal S&T Co., Ltd.

Address:FLAT/RM 1405B 14/F THE BELGIAN BANK BUILDING NOS. 721-725 NATHAN ROAD MONGKOK

Contact person:Mr Green Wu(Manager)

Tel:0086 13533137978

Fax:0086 20 28651601

Email:green_wu@hotmail.com

Skype:green_wu@hotmail.com

facebook:green_wu@hotmail.com

Whatsapp:+8613533137978

Wechat:oneday_kjt

QQ:3839269

Oil fuel HVOF spray equipment SX-8000

- Product name:Thermal spray equipment

- Description:for spraying high qulatiy coating

Introduction:

SX-8000 supersonic flame spraying is a new type of HVOF system, Its principle is that the combustion supporting agen oxygen atomizes the kerosene fully with atomizing nozzle, then they will enter into combustion chamber as flammable mixed gas.It will burn in high temperature and high pressure after the ignition system ignites it. high-temperature and high-pressure supersonic flame flow will be formed after it’s burning in the Laval nozzle. powder feeding system will send the powder material from the area of low pressure into the flame flow, heating accelerated then spray to the workpiece surface to form high quality coatings.

SX-8000 HVOF spray equipment is a spraying equipment of improving on the basis of introduction/ digestion /absorption of foreign advanced equipment and technology.

Compare to other HVOF ,there are eight different notable feature as followings:

1.Kerosene is fuel while oxygen is combustion adjuvant . It is a relatively safe combustion mode.

2.The spraying gun is designed according to rocket motor principle.. The pressure in combustion chamber can get up to 150PSI,The speed of

flame is more than 2000m/s. The output power is huge and can be adjusted without level.

3.Gun sprays powder with radial feeding method. This new method of spraying the powder can be better for melting and delivering well distributed throughout the flame,which

improves the coverage efficiency and quality of the coating;

4. A certain range of temperature range is fixed by system design, the speed raising is as the main target function of structural optimization; The X - ray diffraction test proves that the coating is not only of high strength, high density, but also be stress on the surface;

5. Modular design, high performance PLC control, easy to operate

6. The particle velocity of the combustion design reaches 1100 M / S (3300 to 3900 feet per second), which is significantly faster than the other HVOF system;

7. The coating thickness is more than 1/2 inch (compressive stress coating). The microhardness of the coating is higher than that of any other HVOF system (WC-Co),the hardness is 1450, while the microhardness of other gas HVOF spray gun is only 1100 ~ 900;

8. SX-8000 supersonic flame spraying equipment has achieved excellent high pressure HVOF coating quality, the coating can achieve the binding strength of 90MPa.

The equipment contains: A-intelligent control system B-gas safety center;C-intelligent powder feeder;D-spray gun;E-water chiller;E-the oil storage tank and piping connection.

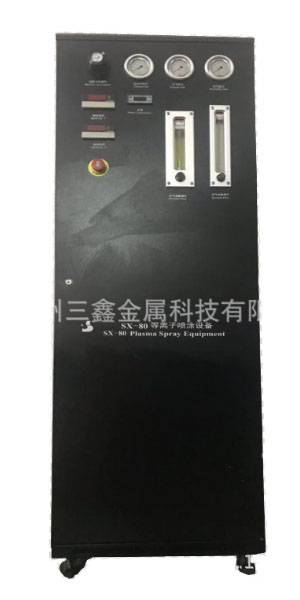

A,intelligent control system

The intelligent control system is the control center of

the whole set of equipmentFeatures of SX-80 human machine

interface intelligent control system SX-80 human machine

interface intelligent control system, The plasma spraying

system has the advanced level of foreign similar products,

superior performance and convenient operation. The

control cabinet adopts PLC touch type control terminal,

which integrates operation, setting, help, display,

process and fault alarm monitoring. It simplifies the

panel design, is convenient to use, and is more simple and intuitive to operate.

B,gas safety center

(special note: because H2 gas is a flammable and explosive dangerous gas, and mass flowmeter is an electrical component, there is a risk of combustion and explosion when electric spark is generated. Therefore, the independent "water, electricity and safety center" specially manufactured and developed by our company provides safety guarantee function for the use of equipment.)

Functional features:

A. Three kinds of gas (H2, N2, ar2) leakage detection

system.

B. Gas leakage alarm device.

C. Cut off the air inlet pipe quickly.

D. Flashback prevention and flameout device of spray gun.

E. Leakage protection, cut-off and alarm device.

F. Current overcurrent protection device.

G. Overvoltage protection device.

H. Water leakage pressure sensing device.

1. Super high water temperature warning, shutdown system.

J. Dust concentration monitoring alarm and shutdown device.

C,intelligent powder feeder

1、PLC and touch screen are used to set parameters to precisely control powder feeding accuracy and speed.

2、The system consists of two sets of independent powder feeding devices. The capacity of the large tank is 20 liters, and the speed of the scraper-type powder feeding is 150 g/min. The small tank adopts the drum-type powder feeding device, which is suitable for feeding various ultra-fine powder and hard-to-deliver powder mixtures.

3、Fully enclosed plastic-steel chassis, free from environmental disturbance such as temperature and humidity, transparent glass door, powder feeding state at a glance.

Powder vibration device, powder tank heating device and weighing device can be selected

D,Spray gun

SX-8000 supersonic flame spraying gun use kerosene as fuel, oxygen for combustion supporting gas, air and water for cooling body, nitrogen is for powder feeding. Gun can work for a long time continuously and stably.

Spray gun parameter

|

Item |

Parameter |

|

Flame speed |

About 2100m/s |

|

Flame temperature |

About 5000℃ |

|

Spray gun power |

150KW(equivalent value) |

|

Powder particle speed |

1100 m/s |

|

Cooling method |

Water |

|

Cool water flow |

9.5L/min |

|

Coating porosity |

<1% |

|

Coating bonding strenth |

>90MPa |

|

Powder size |

10-45μm |

|

Oil pressure and flow |

1.2MPa 0~60L/min |

|

Oxygen pressure and flow |

1.6MPa0~60m3/H |

|

Nitrogen pressure and flow |

0.35~0.4MPa 3~15L/min |

|

Spray gun dimension |

90mmX100mmX350mm |

|

Spray gun weight |

About 4.5Kg |

E, water chiller

Heat exchanger is also called refrigerator or water chiller. We use double motors compressor to make this machine smaller and save space for our customer. The spray gun is cooled down by water, and we use heat exchanger to cool down the high temperature water coming from spray gun, and then use these cooled water to cool down the spray gun again. In this way the spray gun can keep a normal working temperature and prolong the usage life of spray nozzle.

Function characteristic

The range of testing temperature is -4.9℃-94.9℃,dispraying resolution ratio is 0.1℃,controling sensitivity is 0.1℃,offset range is -0.5℃—10℃,used in AC220V input.the instrument use condition:relative humidity less than 90%RH,the temperature is within 0—45℃ with no corrosion and water-proof.

Parameters of cooling system

|

Number |

Item |

Parameter |

||

|

1 |

Size |

2000×780×1910(mm) |

||

|

2 |

Capacity of circulation water tank |

250KG |

||

|

3 |

Capacity of cooling |

35KW |

||

|

4 |

Water temperature fluctuation |

5℃ |

||

|

5 |

Voltage |

3P AC380 50HZ/80HZ |

||

|

6 |

Compressor |

Double compressor |

Place of Origin:Janpan Sanyan(join venture) |

|

|

7 |

Water pressure |

4-8kg adjustable |

Water out |

6 m3/h |

|

8 |

External circulation pump |

Rated power 1.1kw |

Rated current 1.5A |

|

|

9 |

Refrigerants injection quantity |

11kg |

The cooling medium |

F22 |

|

10 |

Fan power |

85W*2 |

||

|

11 |

Input power |

13.5KW |

||

|

12 |

Weight |

450kg |

||